Revolutionizing Mining Industry with Advanced Gold Mining Machinery

Gold mining machinery has transformed the mining industry, revolutionizing the way gold is extracted from the earth. With advanced technology and https://cell-seo.com/dashboard/strategies/922 machinery, the process of mining for gold has become more efficient and productive. This has led to increased output and profits for mining companies, as well as improved safety and environmental practices. In this article, we will explore the impact of advanced gold mining machinery on the industry, and how it is shaping the future of mining.

Revolutionizing the mining industry with advanced gold mining machinery involves the implementation of cutting-edge technology and equipment to improve efficiency, productivity, and safety in the extraction process. This includes the use of state-of-the-art machinery such as electric-powered drills, automated conveyor systems, advanced crushing and grinding equipment, and sophisticated sorting and separation technologies.

By integrating these advanced machinery and technologies, mining companies can achieve higher levels of precision in gold extraction, reduce operational costs, minimize environmental impacts, and enhance overall operational performance. Additionally, the use of advanced machinery allows for real-time monitoring and data analysis, leading to better decision-making and process optimization.

Furthermore, the adoption of advanced gold mining machinery can provide a competitive edge for mining companies, enabling them to maximize production and streamline operations, ultimately leading to increased profitability and sustainability in the industry. Overall, the incorporation of advanced machinery has the potential to revolutionize the gold mining industry, driving advancements in safety, productivity, and environmental stewardship.

The Evolution of Gold Mining Machinery

Gold mining machinery plays a crucial role in the extraction of the precious metal from the earth. From heavy-duty excavators to high-powered crushers, these machines are essential for efficiently processing ore and increasing productivity in the industry. With advances in technology, companies are constantly upgrading their gold mining machinery to maximize efficiency and reduce environmental impact. As the global demand for gold continues to rise, the market for these specialized machines is also growing, making it important for businesses to stay informed about the latest advancements and best practices in operating and maintaining these valuable assets.

The evolution of gold mining machinery has been marked by advancements in technology and engineering. Early gold mining relied on simple tools such as the pan and shovel, but as demand increased, more efficient machinery was developed.

The Industrial Revolution saw the introduction of steam-powered machinery for gold mining, greatly increasing the speed and scale of operations. In the 20th century, the development of diesel-powered machinery further improved efficiency and productivity.

Today, gold mining machinery includes a wide range of equipment such as excavators, trommels, and crushers, all designed to extract and process gold ore more effectively. Additionally, advancements in automation and remote operation have improved safety and reduced the need for manual labor.

Overall, the evolution of gold mining machinery has enabled the industry to meet the growing demand for gold while also minimizing environmental impact and improving worker safety.

Investing in Cutting-Edge Gold Mining Machinery

Investing in cutting-edge gold mining machinery can provide significant benefits for mining companies. Advanced technology in mining machinery can increase efficiency, productivity, and safety at mining sites. This can lead to higher yields and reduced operational costs, ultimately resulting in increased profitability for investors. Cutting-edge equipment often incorporates state-of-the-art automation and remote monitoring capabilities, allowing for more precise and controlled operations. Additionally, modern machinery may have a smaller environmental footprint, which can improve a company’s sustainability efforts and public perception. Overall, investing in innovative gold mining machinery can position a company for long-term success in the industry.

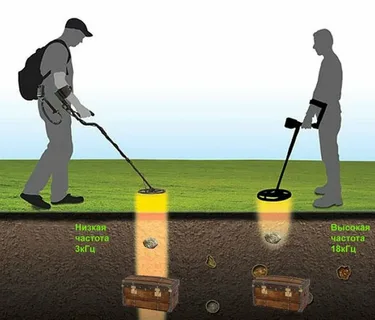

The Role of Technology in Modern Gold Mining Machinery

Technology plays a crucial role in modern gold mining machinery. Advanced equipment such as underground drill rigs, haul trucks, and loaders are equipped with telematics systems that allow for remote monitoring and control, enhancing efficiency and safety in mining operations. Automated and autonomous capabilities in machinery have also improved productivity and reduced the risk of accidents.

Additionally, sophisticated software and data analytics tools are used for resource modeling, mine planning, and optimizing extraction processes. This has led to improved accuracy in predicting gold reserves and optimizing production schedules, resulting in cost savings and increased profitability for mining companies.

In terms of environmental sustainability, technology is also being leveraged to minimize the impact of gold mining operations. For example, advanced water treatment systems and dust control measures are being employed to ensure compliance with regulations and mitigate environmental damage.

Overall, technology has revolutionized the gold mining industry by modernizing equipment, enhancing safety, improving productivity, and promoting sustainability. Its role will continue to grow as mining companies embrace further innovation and digitalization in their operations.

Maximizing Efficiency with Advanced Gold Mining Machinery

Maximizing Efficiency with Advanced Gold Mining Machinery involves seeking out state-of-the-art equipment and technology to streamline operations and improve productivity. This may include investing in high-capacity excavators, advanced ore processing equipment, and cutting-edge automation and control systems. By leveraging the latest machinery and technology, mining companies can increase their output, reduce downtime, and optimize their overall operations. Additionally, advanced gold mining machinery can also help improve safety and environmental sustainability by minimizing waste and reducing the impact on surrounding ecosystems. Ultimately, the use of advanced machinery is crucial for modern gold mining operations looking to stay competitive and maximize their efficiency.

ٍSee Also: Essential Tips for Maintaining and Repairing Excavation Machinery

The Environmental Impact of Gold Mining Machinery

The environmental impact of gold mining machinery is significant and varied. The use of heavy machinery to extract and process gold can result in habitat destruction, soil erosion, and water and air pollution. The clearing of land for mining operations disrupts ecosystems and can lead to loss of biodiversity. In addition, the use of large amounts of water for mining operations can deplete water sources and affect local communities and wildlife. The use of chemicals such as cyanide and mercury in gold processing can also contaminate soil and water, posing serious health risks to humans and wildlife. Overall, the environmental impact of gold mining machinery calls for careful consideration and sustainable practices to mitigate its effects.

Choosing the Right Gold Mining Machinery for Your Operation

The right gold mining machinery for your operation will depend on various factors including the type of deposit you are working with, the scale of your operation, and your budget.

Firstly, it’s important to consider the type of deposit as this will determine the type of equipment needed. For example, if you are working with a placer deposit, a wash plant and sluice boxes may be sufficient, whereas for a hard rock deposit, crushers and mills may be necessary.

The scale of your operation will also play a significant role in the machinery you choose. Smaller operations may be able to get by with smaller, more portable equipment, while larger operations may require heavier machinery such as excavators and trommels.

Finally, your budget will ultimately dictate the machinery you can afford. It’s important to find a balance between investing in quality equipment that will last and staying within your financial means.

Ultimately, choosing the right gold mining machinery for your operation requires careful consideration of the specific needs and constraints of your operation. Researching and consulting with industry professionals can also be helpful in making informed decisions.

The Future of Automation in Gold Mining Machinery

The future of automation in gold mining machinery is expected to continue to advance with the development and implementation of new technologies. Automation has already revolutionized the industry by enabling the use of advanced equipment and machinery that can operate with minimal human intervention. This has resulted in increased efficiency, safety, and productivity in gold mining operations.

In the coming years, automation is expected to further enhance the capabilities of gold mining machinery, with the integration of artificial intelligence, advanced sensors, and real-time data analysis. This will enable machines to make more autonomous decisions and adjustments, further reducing the need for direct human involvement.

Additionally, automation is also expected to play a key role in improving sustainability and environmental impact in gold mining operations. By optimizing processes and reducing the use of resources, automated machinery can help minimize the environmental footprint of gold mining operations.

Overall, the future of automation in gold mining machinery holds great potential for improving the efficiency, safety, and sustainability of the industry. As technology continues to evolve, we can expect to see even more advanced and sophisticated automation solutions being implemented in gold mining operations.

ٍSee Also: The Top Global Exploration Equipment Manufacturing Companies

Maintenance Tips for Extending the Lifespan of Gold Mining Machinery

– Regularly inspect and clean all parts of the machinery to prevent build-up of dirt and debris.

– Lubricate all moving parts to reduce friction and wear.

– Conduct regular maintenance checks on important components such as engines, hydraulic systems, and electrical systems.

– Keep a record of maintenance and repair history to identify any patterns of wear and potential issues.

– Train operators and maintenance personnel on proper use and care of the machinery to prevent misuse and damage.

– Use quality replacement parts and materials to ensure the proper functioning of the equipment.

– Monitor and regulate the temperature and humidity of storage areas to prevent corrosion and deterioration of machinery components.

– Follow manufacturer’s guidelines for recommended maintenance and service schedules.

Exploring the Global Market for Gold Mining Machinery

Exploring the global market for gold mining machinery involves conducting extensive research and analysis to understand the current and potential future demand for equipment used in gold mining operations. This includes evaluating factors such as the overall growth of the gold mining industry, technological advancements driving the need for upgraded machinery, and the geographical areas with the highest concentration of gold mining activity. Additionally, understanding the competitive landscape and key players in the market is essential for gaining insights into market share and potential opportunities for growth and expansion. Overall, a comprehensive exploration of the global market for gold mining machinery requires a deep dive into industry trends, customer needs, and market dynamics to make informed business decisions.

Safety Guidelines for Operating Gold Mining Machinery

The safety guidelines for operating gold mining machinery include:

1. Regular inspection and maintenance of machinery to ensure it is in good working condition.

2. Proper training of operators on the use of machinery and adherence to safety protocols.

3. Use of personal protective equipment such as helmets, gloves, and goggles to prevent accidents and injuries.

4. Clear communication among team members to avoid accidents due to miscommunication.

5. Strict adherence to operating procedures and guidelines to minimize the risk of accidents and equipment failure.

6. Regular monitoring of the working environment for any potential hazards or risks.

7. Adequate ventilation and lighting in work areas to ensure a clear visibility and a safe working environment.

Adherence to these guidelines is crucial in ensuring the safety of workers and the efficient operation of gold mining machinery.

التعليقات مغلقة.